PTFE Tubing Manufacturer

We offer a wide range of high-quality tubing solutions in various colors, sizes, and treatments to meet diverse industry needs.

Contact us today for your PTFE tubing needs.

- 100% virgin material

- OD: 0.6mm - 400mm

- ID: 0.3mm - 375mm

- Extrusion manufacturing

- Flexible / Semi-rigid structure

- Off-the-shelf or custom solutions

Our PTFE Tubing Variants

PTFE Flexible Tubing

Highly flexible, chemical-resistant tubing, ideal for fluid transfer, electrical insulation, and medical applications.

- OD: 2.5mm - 51mm

- ID: 1.5mm - 48mm

- Wall Thickness: 0.5mm - 3.0mm

PTFE Semi-Rigid Tubing

Sturdy yet slightly flexible tubing with low friction, high dielectric strength, and superior resistance to chemicals.

- OD: 18mm - 400mm

- ID: 8mm - 375mm

- Wall Thickness: 2mm - 25mm

PTFE Capillary Tubing

Ultra-thin, precision tubing, ideal for analytical instruments, chromatography, and microfluidic applications.

- OD: 0.6mm - 9.38mm

- ID: 0.30mm - 8.38mm

- Wall Thickness: 0.15mm - 0.5mm

Additional Forming Process

Additional processes (such as SSL braided layer, mechanically or thermally corrugated, and heat-shrinking) can be applied to the initial PTFE tubing.

PTFE SS Braided Tubing

Features a braided stainless steel layer over the PTFE core, enhancing its mechanical strength and pressure resistance.

- OD: 6.3mm - 63.5mm

- ID: 3.0mm - 50.8mm

- Wall Thickness: 1mm - 2mm

- Min.Burst Pressure: 55 - 550 (kg/cm²)

PTFE Convoluted Tubing

Designed with a flexible, ribbed and spiral structure, allowing for easy bending and routing in tight spaces.

- OD: 5.6mm - 79mm

- ID: 3.2mm - 68mm

- Wall Thickness: 1mm, 1.5mm, 2mm

- Length: Max. 25m

PTFE Heat Shrink Tubing

Expands and then shrinks when heat is applied, offering a tight, secure fit over wires or other components.

- Shrink Ratio: 1.7:1, 4:1

- ID Before Shrink: 0.7mm - 9.0mm

- ID After Shrink: 0.4mm - 2.3mm

- Wall Thickness: 0.07/0.10/0.15/0.20mm

Available Colors

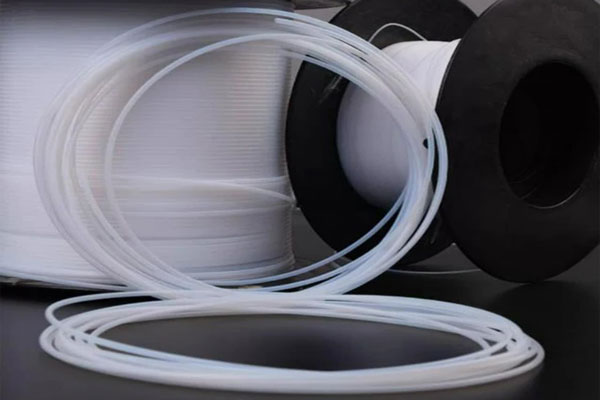

White PTFE Tubing

The natural, uncolored form of PTFE. Its clean, neutral appearance ensures it blends seamlessly into most environments.

Black PTFE Tubing

Achieved by adding carbon black, providing UV resistance and increased durability, used in outdoor or high-temperature applications.

Colored PTFE Tubing

Colorants are added to PTFE resin before it is processed, offers flexibility for color-coded systems or aesthetic appeal.

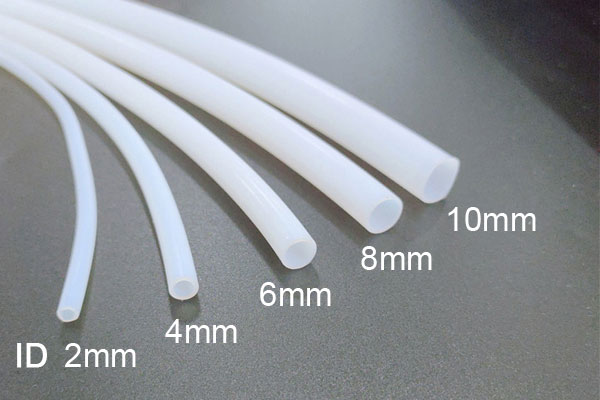

Our PTFE Tubing Sizes

OD | ID | Wall Thickness |

1/8" (3.17mm) | 1.58mm | 0.8mm |

1/4" (6.35mm) | 4.35mm | 1.0mm |

3/8" (9.53mm) | 7.53mm | 1.0mm |

2/5" (10.20mm) | 8.20mm | 1.0mm |

4/5" (20.32mm) | 12.70mm | 1.0mm |

1" (25.40mm) | 15.24mm | 2.0mm |

2" (50.00mm) | 50.0mm | 1.6mm |

PTFE Tubing Manufacturing Methods

- Raw Material Preparation: Fine PTFE powder is selected and mixed with additives if needed.

- Preforming: The PTFE powder is compressed into a solid billet using high pressure.

- Extrusion: The billet is pushed through a die using a paste extrusion machine, shaping it into tubing.

- Sintering: The tubing is heated at 360°C–400°C to solidify and remove the lubricant.

- Cooling & Cutting: The tube is cooled, cut to length, or coiled.

- Finishing & Quality Control: Inspected for ID, OD, wall thickness, strength, and chemical resistance. Additional treatments may be applied.

Contact Us Now

FAQs

Do you use 100% virgin PTFE material?

Yes, all of our PTFE tubing is made from 100% virgin material to ensure the highest quality and performance.

What is the manufacturing method for your PTFE tubing?

Our PTFE tubing is manufactured through extrusion, ensuring precise and consistent quality.

What types of PTFE tubing do you offer?

Our PTFE tubing comes in various variants, including flexible, semi-rigid, capillary, SS braided, convoluted, and heat shrink PTFE tubing.

What are the available sizes of your PTFE tubing?

Our PTFE tubing is available in the following sizes:

- Outer diameters (OD) range from 0.6mm to 400mm.

- Inner diameters (ID) range from 0.3mm to 375mm.

- Wall thicknesses range from 0.15mm to 25mm.

What colors are available for PTFE tubing?

We provide standard white PTFE tubing, black PTFE tubing, and custom-colored PTFE tubing based on your requirements.

Can I request specific certifications for PTFE tubing?

Yes, we can provide certifications based on industry requirements, including ISO, FDA approval, UL ratings, and more.

Do you offer free samples of PTFE tubing?

Yes, we offer samples of our PTFE tubing for evaluation before placing a full order.