PTFE Bushing Manufacturer

We specialize in manufacturing PTFE bushings, precision-molded from virgin PTFE or PTFE with fillers (as needed) to enhance performance.

We also provide custom solutions, from dimensions to colors, shapes, and geometries.

- Virgin PTFE material

- Filler addition options

- Molding process

- Custom design and shapes

By Material Composition

Pure PTFE Bushing

- Made from 100% virgin PTFE.

- Soft and prone to deformation under load.

- Very high temperature resistance (up to 260°C).

- Light loads, corrosion resistance, and chemical processing.

Filled PTFE Bushing

- PTFE mixed with fillers.

- Stronger and more rigid due to fillers.

- Temperature resistance varies depending on the filler type.

- High-load applications, wear resistance, and thermal applications.

PTFE Lined Bushing

- Metal bushing with a PTFE lining.

- Very strong due to metal backing.

- Limited temperature resistance by the backing material.

- High-load, high-speed, and structural support applications.

By Design / Shape

PTFE Cylindrical Bushing

- A simple, straight, and hollow cylindrical sleeve made of PTFE.

- Low friction, high-temperature resistance, excellent chemical resistance.

- Used in rotating, sliding, and linear motion applications where require self-lubrication and wear resistance.

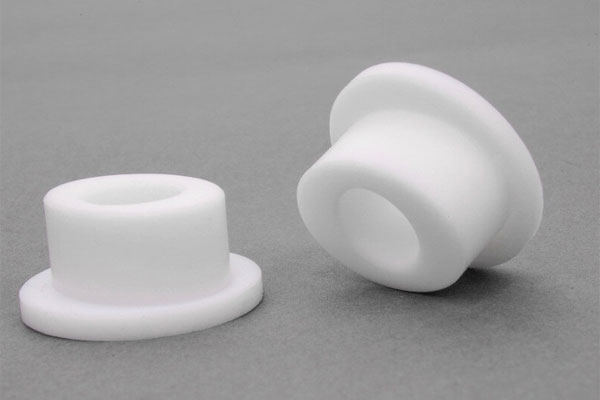

PTFE Flanged Bushing

- A PTFE cylindrical bushing with an extended flange at one end.

- Provides additional support and load distribution.

- Ideal for axial load-bearing applications and where a secure stop or positioning is needed.

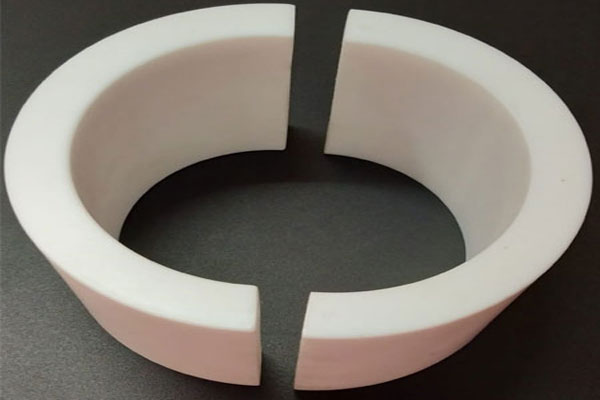

PTFE Split Bushing

- A bushing that is split into two or more sections.

- Simplifies installation and replacement, especially in inaccessible spaces.

- Suitable for shafts or components that experience thermal expansion, ensuring continuous operation.

PTFE Bushing Manufacturing

Compression Molding

Compression molding is a common method for producing PTFE bushings.

- In this process, PTFE powder or resin is placed into a mold cavity.

- Then heat the mold, and apply pressure to the material. This heat and pressure make the PTFE soften and flow, filling the mold’s cavity and taking the shape of the desired bushing.

- The material is then cooled, allowing it to harden and retain the bushing’s shape.

- Depending on the part’s complexity, further finishing processes such as machining, polishing, or testing may be required.

This method is particularly effective for manufacturing PTFE bushings in complex shapes and various sizes, ensuring precise control over dimensions and tolerances.

Filled PTFE Bushings

25% Carbon

- Improved conductivity and load-bearing capacity.

- Suitable for applications with high friction and heat.

25% Glass

- Enhanced dimensional stability, increased strength & rigidity.

- Ideal for structural and high-pressure applications.

15% Graphite

- Excellent self-lubrication and low friction.

- Well-suited for high-speed and low-load applications.

10% PEEK

- Improved mechanical strength and high-temperature stability.

- Best for extreme environments requiring durability.

Contact Us Now

FAQs

Our PTFE bushings are made from virgin PTFE or PTFE with fillers for enhanced performance.

We use compression molding to produce high-quality PTFE bushings with excellent mechanical properties.

Yes, we offer custom PTFE bushings tailored to your size and specification requirements.

Yes, we provide PTFE bushings with fillers such as glass, carbon, graphite, or PEEK to enhance performance.

While standard PTFE has low load-bearing capacity, filled PTFE bushings offer enhanced load resistance.

Absolutely! Our team can help you select the best PTFE bushing based on your application.

Yes, we provide competitive pricing for bulk orders. We also offer free samples to customers for evaluation before bulk orders.