PTFE Rod/Bar Manufacturer

We are a leading manufacturer of PTFE rods, specializing in both extrusion and molding manufacturing methods.

Our PTFE rods are made from virgin PTFE or filled materials (glass fiber, carbon, bronze, and graphite), and they are available in various sizes, shapes, and lengths.

- 100% virgin PTFE

- Filler addition

- Diameter: 10mm - 350mm

- Length: Cut-to-size

- Extruded / Molded

- ISO 9001, FDA, RoHS and ASTM standards

Our PTFE Bar Stock

PTFE Round Bar

- Cylindrical in shape and offer uniformity in diameter.

- Easily machined into custom parts such as seals, bushings, bearings, and gaskets.

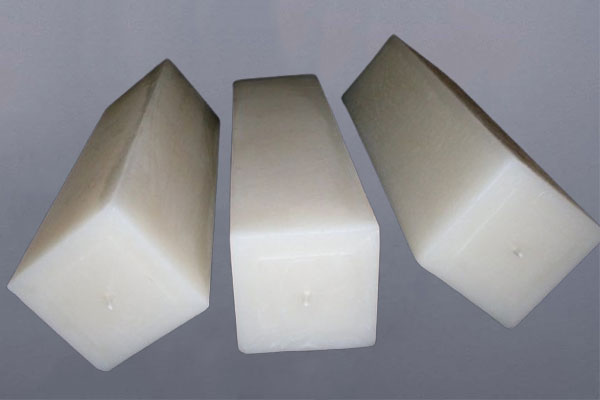

PTFE Square Bar

- Equal side lengths and provide excellent support.

- Ideal for machining parts like spacers, blocks, and electrical insulators.

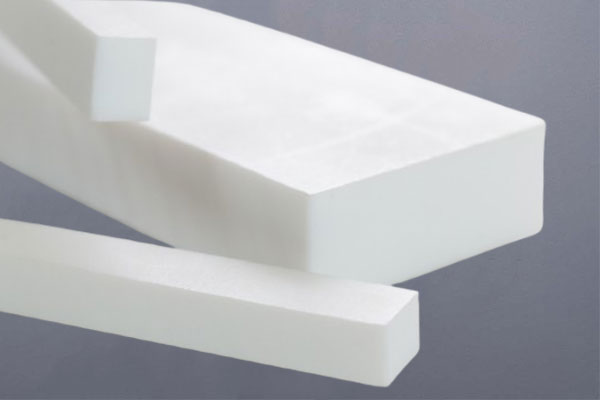

PTFE Rectangular Bar

- Feature a flat shape, offering larger surface areas.

- Cutting into customized parts such as large seals, liners, or structural components.

PTFE Rod Structure

PTFE Solid Rod

- Made entirely of PTFE and are solid throughout.

- Can be easily machined to create custom parts.

- Tends to be stronger and more durable because it is fully solid and can handle higher mechanical stress.

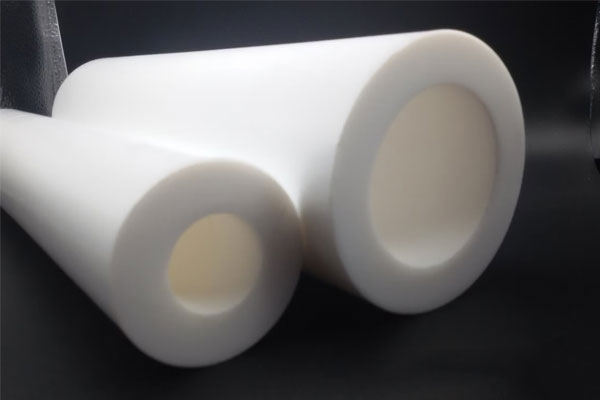

PTFE Hollow Rod

- Have a cylindrical shape with a hollow center.

- Can also be machined, but may require additional fabrication steps.

- May not handle the same mechanical stresses as solid rods due to the hollow core reducing its structural integrity.

PTFE Rod Manufacturing

1. Compression Molding

Molded PTFE rods are created by placing PTFE powder into a mold and then heating it under pressure to form a solid, uniform shape.

PTFE rods made through compression molding have the following features:

- Higher Density

- Smoother Surface Finish

- Higher Strength and Durability

- Larger Diameters Size Availability

- More Expensive

2. Extrusion

Extruded PTFE rods are formed by forcing PTFE resin through a die under high pressure to create a continuous rod, which is then cooled and cut to length.

PTFE rods made through extrusion process have the following features:

- Less dense

- Softer

- Available in smaller diameters

- Less expensive

Filled PTFE Rod

Filled PTFE rods are a variation of the standard PTFE material that is reinforced with additives like glass fiber, carbon, bronze, or graphite to improve its mechanical properties.

Glass Filled

- 15% to 30% glass fibers

- Increased strength & stiffness

- Improved heat resistance

- Reduced creep

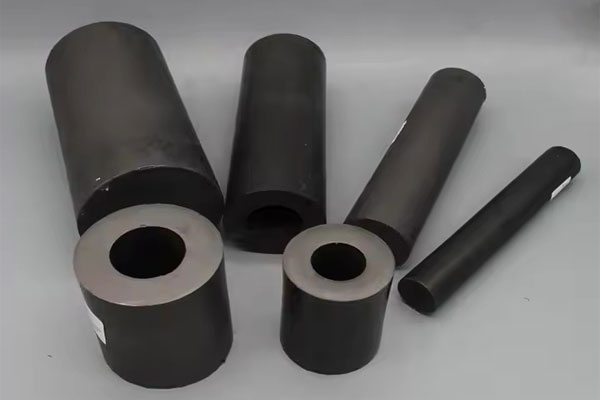

Carbon Filled

- 10% to 25% carbon particles

- Enhanced conductivity

- Improved wear resistance

- Lubricating properties

Bronze Filled

- 10% to 30% bronze powder

- Improved wear resistance

- Self-lubricating effect

- Improved thermal conductivity

Graphite Filled

- 5% to 25% graphite particles

- Low friction & wear resistance

- Enhances lubrication properties

- Improved thermal conductivity

Contact Us Now

FAQs

We manufacture PTFE rods using virgin PTFE or filled PTFE (including glass fiber, carbon, bronze, or graphite-filled PTFE).

We use extrusion and molding methods to manufacture our PTFE rods.

Extruded PTFE rods are continuous-length products with excellent consistency, while molded PTFE rods are produced in specific lengths with higher density and better mechanical properties.

The diameter of our PTFE round rods ranges from 10mm to 350mm.

Yes, we can produce PTFE rods in custom diameters and lengths based on customer requirements.

While our standard PTFE rods are typically white, we can provide colored PTFE rods upon request.

Yes, we offer CNC machining, cutting, and shaping services for customized PTFE components.